What is the best type of render?

With so many different types of render available, how do you make the right choice?

Render manufacturers such as JUB are always looking for new ways to blend different materials to come up with the newest render technologies. This is the way to move forward so applicators can benefit from easier application processes and lower maintenance demands.

Back in the day, render used to be a mix of cement, sand and aggregates. This type of render is now classed as old-fashioned since it can’t compete with the appearance, longevity and durability that modern renders provide.

Compared to conventional render, modern options can have many additional characteristics. For example, you will find that a lot of renders have been reinforced to offer water-resistant, algae-resistant and other features.

All external renders you find in the JUB product catalogue offer these features in addition to being UV-resistant. Generally speaking, newer renders like ours are divided into three main categories.

Types of External Renders

Each type of render will have its specific requirements of how to be applied but with the most common ones such as acrylic and silicone, it will usually need one coat that is about 1mm - 4mm.

The costs for each type of external render will also vary depending on how much preparation work is required, the granular sizes of the filler selected and the performance.

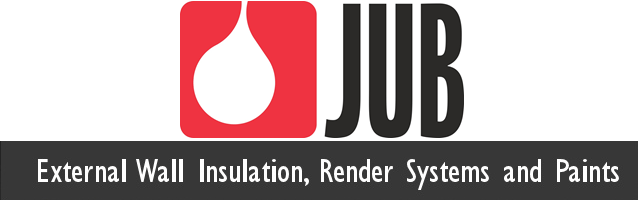

Acrylic render is made by adding acrylic resin to the mix. This type of render is on the cost-effective side and is one of the most commonly used renders in façade systems. Due to its production and binding process, acrylic renders offer the biggest variety of colour shades and textures. Our acrylic renders come in ready-mixed tubs, which means they can be directly applied to the substrate.

The main difference between acrylic and silicone renders is within the price bracket and the performance. Acrylic renders wouldn’t be the ideal option for houses or buildings with a lot of traffic or congestion since they can pick up atmospheric loads easier than silicone render.

Silicone external renders have gained the most popularity in recent years since it offers so much more than the more traditional solutions. It is a silicone resin-based render, which has been mixed with silicone to provide much better performance and durability.

Our range of silicone renders come in a variety of shades and offer superior water resistance, a long life span and reduced adhesion of dust and other dirt to the surface. Just like acrylic external renders, silicone topcoats don’t require any mixing on site.

The main advantage of our silicone renders is that they are superior in water resistance. This means that once dried water will simply slide off it, which can be considered as a self-cleaning effect. This type of render is highly recommended for houses and buildings in areas that experience high humidity or intense atmospheric loads.

Silicone render is quite versatile and is suitable for modern housing, residential projects and commercial facilities.

Mineral renders are cement-based and are bound by lime and polymers to achieve flexibility and breathability when applied. It is again budget-friendly just like acrylic renders. Unlike silicone and acrylic renders, mineral finishes come as a dry mix so they will need to be mixed with water on site.

Mineral renders offer a quick drying time, however, the time is then consumed because, after application, it needs to be painted. The paint seals the render and achieves a long-term solution.

We have a wide range of

external paints available that can be used over mineral render and help achieve a long-lasting façade system.

Lime

Lime render is somehow being brought back as an option on the market. However, it is a specialist type of render that requires special preparation and aftercare. It again comes as a dry mix to be prepared for application on-site.

Getting the mixture and application technique right can be tricky so it is highly recommended that lime render is applied by applicators that have specialist knowledge on the subject. An important thing to point out as well is that lime render can be irritant to the skin and applicators must wear protective gear.

Since it is one of the oldest renders, it is commonly used on Grade II listed buildings or heritage sites, where renovation needs to be like-for-like.

Monocouche

Monocouche render arrives on-site as a dry mix to be then blended with water. It is suitable for brickwork and blockwork and its main advantage is that it’s a one-coat render.

This type of render offers a durable finish and fast application but they have less water-resistant characteristics. This means that over time monocouche can absorb dirt easier, which can then require more maintenance.

Types of Render You Won’t Find Anywhere Else

Here at JUB, we have manufactured a series of silicone, silicate and siloxanised renders that have unique characteristics. These include winter-friendly, self-cleaning and shade durability formulas.

Our Trend finish is a range of heat-reflective renders utilising darker colours. We developed a breakthrough tinting process that incorporates the new technology of IR Reflexion.

What this does is enable the specification of renders with a light intensity down to 5. This means that the surface temperature of the render is reduced by 15℃ so there are no more limits to using dark coloured renders.

The Trend topcoat and can be used on all types of buildings including large areas, south-facing facades and will not require any form of paint coat to gain a consistent finish.

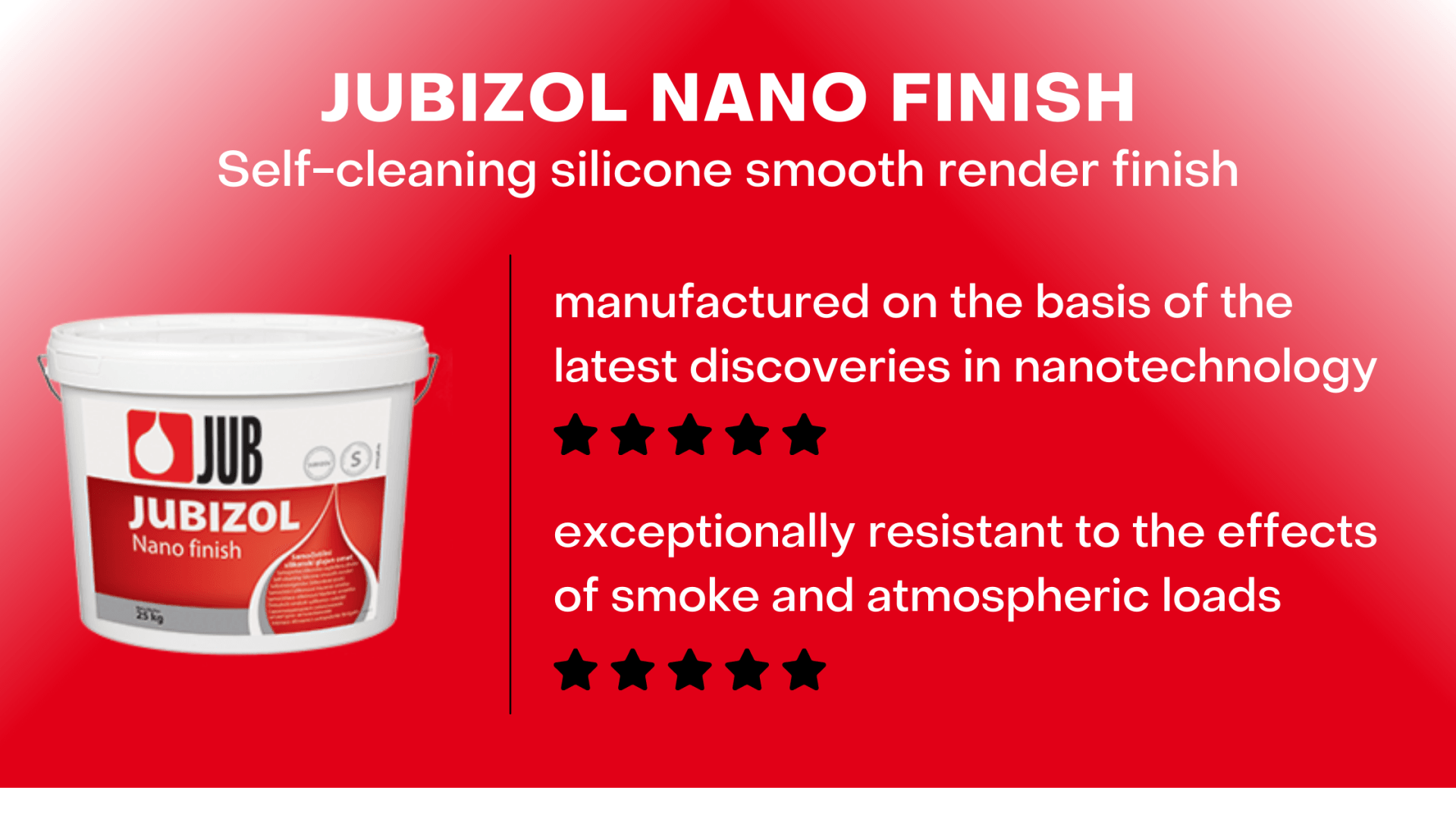

Our Nano finish is a thin-coat high-quality self-cleaning render, whose key components are made in accordance with the latest discoveries in nanotechnologies. Due to a high level of silicone binders and siloxane additives, façade surfaces treated with Nano is more resistant to dust, soot and dirt.

The self-cleaning effect is therefore achieved in places exposed to precipitation. The render adheres well to all types of fine-coarse construction surfaces and base renders of façade thermal insulating systems.

Unixil is a thin-coat render made on the basis of polymeric binders, with selected ratios between fine and coarse filling materials and a combination of modern thickeners, moisteners and siloxane additives. It has a typical evenly grained surface.

This render provides decorative protection to façade wall surfaces of all types of buildings including multi-storey buildings with small projecting roofs. Due to relatively high water-vapour permeability, which is typical for acrylic renders, it may also be applied as the final render in contact façade thermal insulating systems based on mineral wool.

Unixil is also available in a winter grade for use in temperature from 1deg C to 15 deg C and up to 95% humidity.

If you would like to learn more about these types of renders or are interested to learn why you should choose our JUB renders, please get in touch. Call our office on 0845 688 9866 or email us at info@jub.org.uk.

Why Silicone Render is the Best Choice for a Property’s Exterior: Benefits, Application & Aesthetics